Lightweight

ECA block is a highly porous substance and has a density range of 650 to 950 kg/m3, which reduces its deadweight. This makes it easier to transport and faster to carry around, which reduces the structural and labour cost of the building.

high resistance to water absorption

ECA block is made of ECA round palletes that give it the honeycomb structure and higher compressive strength compared to ordinary bricks. This makes the final structure that much stronger. This is why ECA block is lighter but stronger.

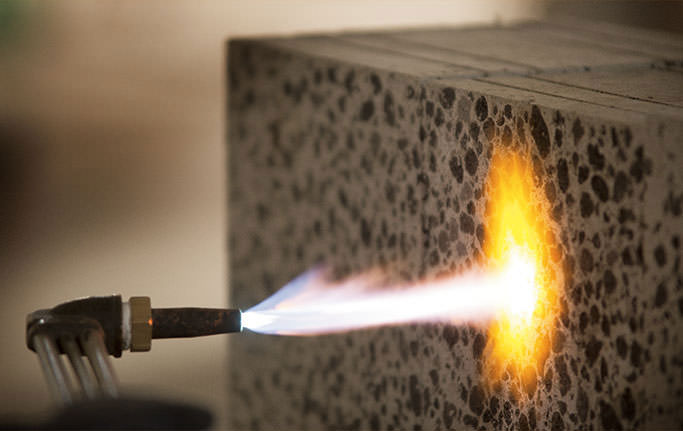

Fire Resistant

The main substance of ECA block is Expanded Clay Aggregate which is formed at 1200oC. This exceeds the statutory requirements of Standard Building Code and provides a significant level of life and property protection against fire.

thermal insulation

ECA block has high thermal coefficient, which shields the interiors from external heat and cold. This results in cost savings for heating and cooling.

earthquake resistant

The superior compressive strength of ECA block makes it naturally capable of withstanding a high intensity quake.

non reactive

ECA block has strong chemical resistance against acidic and alkaline substances, which helps to maintain the pH value of 7, which is considered neutral. This makes it nonreactive to substances, which in turn improves its longevity.

superior acoustic insulation

A 20 cm wide ECA block can prevent up to 46 db of noise. This renders the surrounding a lot more peaceful, especially when offices or homes are in close proximity to main roads.

termite & pest resistant

Termites cannot penetrate the superior protection of ECA block. This enhances both the safety and longevity of structure formed using ECA block.

easier to build

As the ECA blocks are lighter, it is easier for labourers or machines to carry them to higher floor. This reduces labour and machine cost while improving efficiency considerably.

benefits for

construction industry

easier to transport

ECA blocks are bigger, lighter, stronger and more durable than conventional bricks. This makes it that much easier and more efficient to transport them without damages to the blocks even in case of less than ideal transport infrastructure.

easy to modify

ECA blocks can be drilled, nailed and shaped easily. They can also be easily coated with plaster or paint to decorate the walls as required. Concealed or conventional wirings and pipes can also be installed easily.

environmentally friendly

ECA is credited by Leadership in Energy and Environmental Design (LEED) and US Green Building Council (USGBC) as a "green" alternative to traditional construction materials. Indian Green Building Council (IGBC) also recommends its use in India. ECA generates no pollutants or hazardous wastes.

efficient use to labour

As the ECA blocks are bigger and lighter, the required structure can be made much faster and with less effort, which directly translates to significant cost benefit.

direct cost savings

Due to its smooth surface and large dimension, mortar expense is reduced by over 70%.

technical

specifications

technical specification of eca block

-

Size

600 x 200 x 230 mm

600 x 200 x 150 mm

600 x 200 x 100 mm

-

Dry Density

600 to 750 kg.m3

-

Compressive Strength

3.5 to 5.0 N/mm2

-

Thermal Conductivity

0.14 to 0.18 W/mk

-

Sound Absorption

up to 46 dB

get in touch

Nexus Buildcon Solutions

Off N. H. 8A (Bamanbor-Morvi),

Mesariya Road, Rangapar Village,

Tal. Wakaner, Dist. Rajkot, Gujarat, India

Copyright 2015 Nexus Buildcon Solutions.